machine learning

Overview

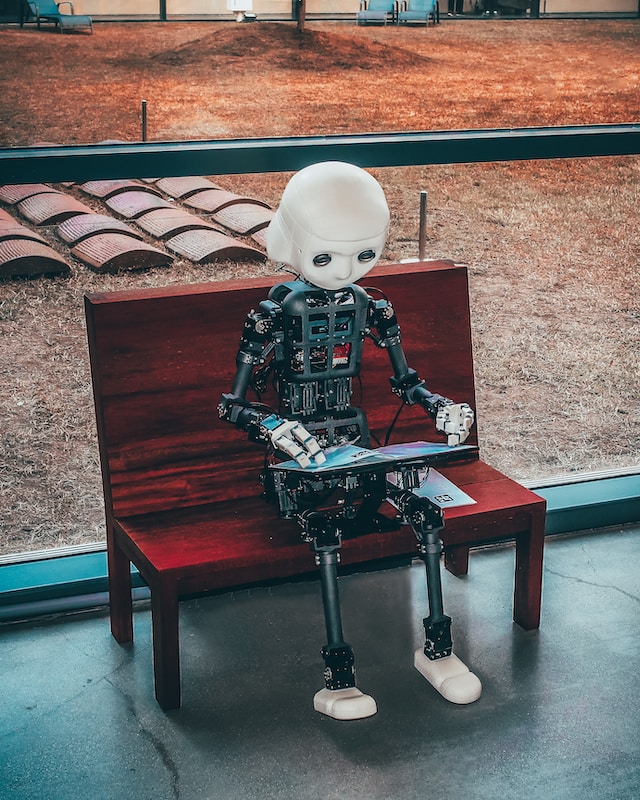

Artificial Intelligence (AI) and Machine Learning (ML) in particular are finding widespread applications in many industries. However, many customers across industry verticals, contemplating the adoption of ML in their business and IT process automation, have unreasonable expectations about the capabilities of these learning machines. Many imagine or opine that ML can completely take over human tasks. We will take a closer look at ML, explain the learning process and set the right expectations for these customers.

Using machine learning and analytics, KEMS helps unlock the power of data (like project documentation, test artifacts, defect logs, test results, production incidents, etc.) and drives automation and innovation, improving QA efficiencies beyond the reach of traditional QA practices.

Infosys AI/ML-led QA offering, based on a scientific approach using both supervised and unsupervised methods, helps unearth defects beforehand, optimize testing and predict failure points, thus reducing the overall cost and achieving high customer satisfaction.

Our approach to artificial intelligence (AI) / machine learning (ML) based quality assurance is design-based, complying with the following steps – Discover > Learn > Sense > Respond cycle. The knowledge base constantly helps in storing and building pattern, which in turn helps in self-learning and responding to actions.

our approach to delivering inovation machine learning solutions

We follow a four-step process to develop machine learning model that help business to improve their bottom line.

Understanding data

We gather data from the right source analyze it tohave a better understanding of your business problem

Data preparations

We clean and transform data to improve it’s quality and ensure that it can be easily processed and analyzed

Model building

We build train models, test their efficiency and iterate until the desired accuracy is achieved

Evaluation and deployment

Once your’s happy with the evaluation, we go ahead model deployment

Healthcare&MedicalDevices

Non-invasive wearable sensors, for real time health monitoring and KEMS -centric healthcare

Automotive

Vehicle telematics to provide to fleet management and operational efficiency

Manufacturing

Shop-floor and end-products connectivity for improved quality, productivity and supply chain optimization

Mining

Real time monitoring of mine equipment, management of assets, worker health and safety

Utilities, oil & Gas

Reliable, integrated energy and assets management to improve energy efficiency

Retail

Supply chain optimization along with real time situational awareness to improve customer experience and return management

Success Stories

CASE STUDIES